- Home Page

- Company Profile

-

Our Products

- Plastic Moulds

- Moulds & Die Casting

- Plastic Mould

- Sand Moulds & Die Casting

- Light Glass Moulds

- Mould base For Plastic Mould

- Aluminum Hard Moulds & Die Casting

- Plastic Moulds Base

- PDC Mould Pressure Die Casting

- Moulds

- Aluminium High Moulds & Die Casting

- Premium Moulds & Die Casting

- Shell Moulds & Die Casting

- Aluminium High Pressure Moulds & Die Casting

- Black Moulds & Die Casting

- Industrial Moulds and Die Casting

- Gravity Aluminium Moulds & Die Casting

- Shell Moulds and Die Casting

- Aluminium Moulds and Die Casting

- High Pressure Moulds & Die Casting

- Moulds and Die Casting

- Industrial Moulds & Die Casting

- Moulds & Die Casting

- Manual MS Moulds & Die Casting

- Coated MS Moulds & Die Casting

- Coated Mild Steel Moulds & Die Casting

- Industrial Sheel Moulds and Die Casting

- Gravity Moulds & Die Casting

- Aluminium Moulds & Die Casting

- Manual Mild Steel Moulds & Die Casting

- Coated Moulds & Die Casting

- MS Gravity Moulds & Die Casting

- Pressure Die Casting

- Plastic Moulding Dies

- Plastic Mold Maker

- Plastic Component Mold

- Plastic Die Maker

- Plastic Injection Molding

- Plastic Injection Molding Parts

- Plastic Mold Die

- Plastic Moulding Dies

- Plastic Rubber Moulding Die

- PVC Bike Handle Grip Mould

- Plastic Components Mold

- Plastic Mold Die

- Bike Side Handle Grip Mold

- Plastic Injection Molding

- Plastic Mold Maker

- Plastic Die Mould

- Plastic Cutlery Die Mold

- Plastic Moulding Die Maker

- Plastic Mug Mould Die

- GITTI Mold Plastic Products

- Safety Goggles Mould

- Plastic Toys Mold Die Making

- Plastic Spoon Die Mold

- Plastic Moulding Dies, Packaging Type Wooden Box

- Plastic Molds

- Plastic Injection Molding Parts

- Plastic Spoon Mould

- Plastic Plate Casting Mould Die

- Safety Glass Mold For Covid19 Protection

- Plastic Rubber Moulding Die

- Plastic Mold Manufacturing

- Plastic Molding Die Maker

- Plastic Mold maker in USA

- Plastic Molding

- custom plastic molds

- plastic mold

- Moulding Die

- Die Moulds

- MS Die Moulds

- Rubber Die Moulds

- DIE MOULD MANUFACTURER

- Die Casting Mould

- Aluminium Casting Mold

- Plastic Molding Die Maker

- RO Inline Mold Die

- Carbon Filter Jali Mold Die

- Sheet Metal Door Dies

- Plastic Mold Die Maker

- Mould Making Service

- Hot Runner Injection Mold

- Plastic Injection Mould Manufacturer

- Bakelite Die Maker

- MS Die Moulds

- Plastic Injection Mould

- Injection Moulding Dies

- Plastic Cabinets Die Mold Maker

- Egg Tray Mould

- Plastic Molding Die Maker

- Zig Zag Shape Paver Block Mold

- Cosmic Paver Mould

- I Shape Paver Mould

- Interlocking Paver Tile Mold

- PVC Paver Mould

- Cable Box Mould

- Industrial Mould

- Reflector Die Mold

- Aluminiun Casting Mold

- Plastic Buckle Mold

- Trophy Mold Die

- Plastic Product Molds

- Plastic Junction Box Mould

- Shower Die Casting Mold

- Square Plastic Injection Mold

- Cable Tie Injection Mold

- RO Pump Mold

- Industrial Plastic Mold

- Aluminium Casting mold maker

- Industrial Plastic Injection Mold

- Reflector Plastic Die Mould

- Industrial Reflector Mold

- Rectangular Reflector Mold

- Plastic Crockery Mould

- Plastic Injection Mold

- Plastic Crockery Mould

- Mild Steel Injection Mould

- Pump Parts Mold

- Flip Top Plastic Cap Mould

- Automotive Plastic Mouldings

- Sheet Metal Die Mould

- Comb Applicator Mold

- Plastic Cap Mould

- Door Bending Sheet Die

- Injection Mould

- Zinc Casting Mold

- Plastic Injection Mould

- Molding Machines

- plastic mould makers

- plastic mold maker in Europe

- Plastic Mold Maker in Middle east

- Plastic Mold Maker in UAE

- Plastic Mold Maker in Kuwait

- Plastic Mold Maker in Saudi Arabia

- plastic mold making

- Plastic Mold Maker in Germany

- injection mold making

- Plastic Mold Maker in America

- custom injection mold makers

- injection mold makers

- Submersible Pump Control Panels

- submersible panel enclosure box suppliers in india

- Submersible Panel Enclosure Box Cabinet

- Submersible Panel enclosure box

- submersible panel enclosure box suppliers

- Mini Submersible Control Cabinet

- Single Phase Submersible Control enclosure box

- Plastic Submersible Control Cabinet Encloser Chassis Box

- Submersible Plastic Control Cabinet Encloser Chassis Box

- Submersible Plastic Cabinet Box Submersible Plastic Encloser chassis

- Plastic Enclosures Mould

- Submersible Plastic Encloser chassis Submersible plastic cases boxes

- Submersible Plastic Cabinet Box Submersible Plastic Encloser Box Outer Body

- Plastic Square Box Submersible Plastic Control Cabinet Box

- Filter Caps

- Plastic Brick Mould

- Rubber Parts

- Contact Us

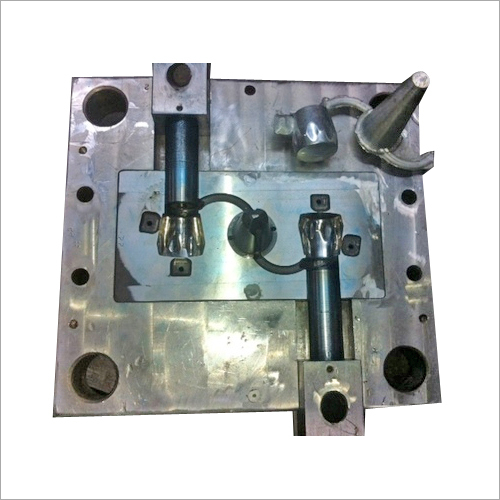

Industrial Die Moulds for RO SMPS Cabinets

MOQ : 2000 Pieces

Industrial Die Moulds for RO SMPS Cabinets Specification

- Mould Base

- P20 Steel

- Working Process

- CNC Machining, EDM, Polishing, Milling, Drilling

- Core Material

- H13/NAK80/2738 as per client requirement

- Tolerance

- 0.01mm

- Life Span

- 500,000 to 1,000,000 shots

- Material

- High Grade Steel/Alloy Steel

- Shaping Mode

- Plastic Injection Mould

- Punch Dies

- Precision Hardened Steel Punches

- Die Head

- Custom Designed for RO SMPS Cabinet

- Runner System

- Hot/Cold Runner as per client need

- Application

- RO SMPS Cabinet Plastic Enclosure Manufacturing

- Surface Hardness

- HRC 48-52

- Injection System

- Pin/Side Gate Injection

- Mould Size

- Customized as per RO SMPS Cabinet Design

- Ejector System

- Pin Ejection with Precise Alignment

- Design Software

- AutoCAD, UG, Pro-E, SolidWorks

- Cooling System

- Optimized Water Channel Design

- Mould Finish

- High Gloss/Matte as required

- Lead Time

- 35-45 Days

- Cavity Number

- Single/Multiple as per order specification

About Industrial Die Moulds for RO SMPS Cabinets

Discover the pristine, hot-selling Industrial Die Moulds for RO SMPS Cabinetsan astounding solution for manufacturers seeking superior quality. As a popular choice among exporters and suppliers in India, these moulds feature high gloss or matte finishes, customized sizes, and noteworthy surface hardness of HRC 48-52. Optimized water channel cooling and precise pin ejection ensure efficient production. Tailored single/multiple cavities and advanced design software support your unique specifications. Enjoy a hot deal with longevity of 500,000 to 1,000,000 shots, ensuring your RO SMPS Cabinet enclosure manufacturing remains flawless, precise, and reliable.

Usage & Application of Industrial Die Moulds for RO SMPS Cabinets

Industrial Die Moulds for RO SMPS Cabinets are engineered for manufacturing plastic enclosures used in RO water purifier systems. They adapt to various application media, supporting both single and mass production runs. Widely used by producers, manufacturers, and exporters, these moulds accommodate custom designs, ensuring each cabinet meets exacting standards. Their usage encompasses high-precision shaping modes tailored for plastic injection processes, making them integral to the assembly and production lines across the RO SMPS cabinet sector.

Packaging Details, Main Domestic Market & Payment Terms

Each mould is securely packaged for seamless shipment and safe handling, ensuring pristine condition upon arrival. Products are dispatched promptly across the main domestic markets in India, catering to traders, suppliers, and wholesalers. Our competitive list price, flexible payment terms, and reliable delivery schedules make transactions hassle-free. All deliveries are tracked throughout the shipment process, offering customers assurance from order placement to product receipt.

Usage & Application of Industrial Die Moulds for RO SMPS Cabinets

Industrial Die Moulds for RO SMPS Cabinets are engineered for manufacturing plastic enclosures used in RO water purifier systems. They adapt to various application media, supporting both single and mass production runs. Widely used by producers, manufacturers, and exporters, these moulds accommodate custom designs, ensuring each cabinet meets exacting standards. Their usage encompasses high-precision shaping modes tailored for plastic injection processes, making them integral to the assembly and production lines across the RO SMPS cabinet sector.

Packaging Details, Main Domestic Market & Payment Terms

Each mould is securely packaged for seamless shipment and safe handling, ensuring pristine condition upon arrival. Products are dispatched promptly across the main domestic markets in India, catering to traders, suppliers, and wholesalers. Our competitive list price, flexible payment terms, and reliable delivery schedules make transactions hassle-free. All deliveries are tracked throughout the shipment process, offering customers assurance from order placement to product receipt.

FAQs of Industrial Die Moulds for RO SMPS Cabinets:

Q: How are the Industrial Die Moulds for RO SMPS Cabinets customized according to specific requirements?

A: Industrial Die Moulds for RO SMPS Cabinets are customized based on client specifications for cavity number, mould finish, size, and core materials to precisely match the design requirements of the RO SMPS cabinet enclosures.Q: What benefits do the optimized water channel cooling and precise pin ejection offer?

A: The optimized water channel design ensures uniform cooling, reducing cycle times and improving product integrity. Precise pin ejection allows for flawless removal of finished items, minimizing damage and deformation during production.Q: When can I expect the industrial die moulds to be dispatched after placing my order?

A: Generally, the lead time for production is 35-45 days. Once completed, moulds are carefully packaged and dispatched to the specified delivery address, adhering to agreed shipment schedules.Q: Where is the main domestic market for these die moulds located?

A: These die moulds primarily serve customers across major cities and industrial hubs in India, with wide availability for wholesalers, traders, and manufacturers seeking reliable solutions.Q: What is the process for manufacturing the RO SMPS cabinet die moulds?

A: The manufacturing process involves advanced CNC machining, EDM, polishing, milling, and drilling. Each mould head and punch die are custom-designed for RO SMPS cabinets, using high-grade steel and alloy steel to ensure durability and precise shaping.Q: How long is the expected life span of these die moulds?

A: The moulds are engineered for longevity, with an estimated life span of 500,000 to 1,000,000 shots, allowing for consistent, high-quality production over extensive cycles.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Plastic Moulds Category

Plastic Mould

Minimum Order Quantity : 1 Piece

Life Span : Up to 1 Million Shots

Tolerance : 0.01 mm

Punch Dies : Hardened Steel

Core Material : HighGrade Steel

Material : Steel

Zinc Die Casting Moulds

Minimum Order Quantity : 1 Piece

Life Span : Up to 1,000,000 Shots

Tolerance : 0.01mm

Punch Dies : Customized as per Design

Core Material : Hardened Steel

Material : Metal

Plastic Mould Maker

Minimum Order Quantity : 1 Piece

Life Span : Up to 1,000,000 shots

Tolerance : 0.01 mm

Punch Dies : Customizable Steel Dies

Core Material : Highgrade Steel

Material : Steel

High Pressure Die Casting Mould

Minimum Order Quantity : 1 Piece

Life Span : Up to 100,000 shots (varies with maintenance)

Tolerance : 0.01 mm

Punch Dies : Highprecision punch dies included

Core Material : Hardened tool steel

Material : Steel

Send Inquiry

Send Inquiry