- Home Page

- Company Profile

-

Our Products

- Plastic Moulds

- Moulds & Die Casting

- Plastic Mould

- Sand Moulds & Die Casting

- Light Glass Moulds

- Mould base For Plastic Mould

- Aluminum Hard Moulds & Die Casting

- Plastic Moulds Base

- PDC Mould Pressure Die Casting

- Moulds

- Aluminium High Moulds & Die Casting

- Premium Moulds & Die Casting

- Shell Moulds & Die Casting

- Aluminium High Pressure Moulds & Die Casting

- Black Moulds & Die Casting

- Industrial Moulds and Die Casting

- Gravity Aluminium Moulds & Die Casting

- Shell Moulds and Die Casting

- Aluminium Moulds and Die Casting

- High Pressure Moulds & Die Casting

- Moulds and Die Casting

- Industrial Moulds & Die Casting

- Moulds & Die Casting

- Manual MS Moulds & Die Casting

- Coated MS Moulds & Die Casting

- Coated Mild Steel Moulds & Die Casting

- Industrial Sheel Moulds and Die Casting

- Gravity Moulds & Die Casting

- Aluminium Moulds & Die Casting

- Manual Mild Steel Moulds & Die Casting

- Coated Moulds & Die Casting

- MS Gravity Moulds & Die Casting

- Pressure Die Casting

- Plastic Moulding Dies

- Plastic Mold Maker

- Plastic Component Mold

- Plastic Die Maker

- Plastic Injection Molding

- Plastic Injection Molding Parts

- Plastic Mold Die

- Plastic Moulding Dies

- Plastic Rubber Moulding Die

- PVC Bike Handle Grip Mould

- Plastic Components Mold

- Plastic Mold Die

- Bike Side Handle Grip Mold

- Plastic Injection Molding

- Plastic Mold Maker

- Plastic Die Mould

- Plastic Cutlery Die Mold

- Plastic Moulding Die Maker

- Plastic Mug Mould Die

- GITTI Mold Plastic Products

- Safety Goggles Mould

- Plastic Toys Mold Die Making

- Plastic Spoon Die Mold

- Plastic Moulding Dies, Packaging Type Wooden Box

- Plastic Molds

- Plastic Injection Molding Parts

- Plastic Spoon Mould

- Plastic Plate Casting Mould Die

- Safety Glass Mold For Covid19 Protection

- Plastic Rubber Moulding Die

- Plastic Mold Manufacturing

- Plastic Molding Die Maker

- Plastic Mold maker in USA

- Plastic Molding

- custom plastic molds

- plastic mold

- Moulding Die

- Die Moulds

- MS Die Moulds

- Rubber Die Moulds

- DIE MOULD MANUFACTURER

- Die Casting Mould

- Aluminium Casting Mold

- Plastic Molding Die Maker

- RO Inline Mold Die

- Carbon Filter Jali Mold Die

- Sheet Metal Door Dies

- Plastic Mold Die Maker

- Mould Making Service

- Hot Runner Injection Mold

- Plastic Injection Mould Manufacturer

- Bakelite Die Maker

- MS Die Moulds

- Plastic Injection Mould

- Injection Moulding Dies

- Plastic Cabinets Die Mold Maker

- Egg Tray Mould

- Plastic Molding Die Maker

- Zig Zag Shape Paver Block Mold

- Cosmic Paver Mould

- I Shape Paver Mould

- Interlocking Paver Tile Mold

- PVC Paver Mould

- Cable Box Mould

- Industrial Mould

- Reflector Die Mold

- Aluminiun Casting Mold

- Plastic Buckle Mold

- Trophy Mold Die

- Plastic Product Molds

- Plastic Junction Box Mould

- Shower Die Casting Mold

- Square Plastic Injection Mold

- Cable Tie Injection Mold

- RO Pump Mold

- Industrial Plastic Mold

- Aluminium Casting mold maker

- Industrial Plastic Injection Mold

- Reflector Plastic Die Mould

- Industrial Reflector Mold

- Rectangular Reflector Mold

- Plastic Crockery Mould

- Plastic Injection Mold

- Plastic Crockery Mould

- Mild Steel Injection Mould

- Pump Parts Mold

- Flip Top Plastic Cap Mould

- Automotive Plastic Mouldings

- Sheet Metal Die Mould

- Comb Applicator Mold

- Plastic Cap Mould

- Door Bending Sheet Die

- Injection Mould

- Zinc Casting Mold

- Plastic Injection Mould

- Molding Machines

- plastic mould makers

- plastic mold maker in Europe

- Plastic Mold Maker in Middle east

- Plastic Mold Maker in UAE

- Plastic Mold Maker in Kuwait

- Plastic Mold Maker in Saudi Arabia

- plastic mold making

- Plastic Mold Maker in Germany

- injection mold making

- Plastic Mold Maker in America

- custom injection mold makers

- injection mold makers

- Submersible Pump Control Panels

- submersible panel enclosure box suppliers in india

- Submersible Panel Enclosure Box Cabinet

- Submersible Panel enclosure box

- submersible panel enclosure box suppliers

- Mini Submersible Control Cabinet

- Single Phase Submersible Control enclosure box

- Plastic Submersible Control Cabinet Encloser Chassis Box

- Submersible Plastic Control Cabinet Encloser Chassis Box

- Submersible Plastic Cabinet Box Submersible Plastic Encloser chassis

- Plastic Enclosures Mould

- Submersible Plastic Encloser chassis Submersible plastic cases boxes

- Submersible Plastic Cabinet Box Submersible Plastic Encloser Box Outer Body

- Plastic Square Box Submersible Plastic Control Cabinet Box

- Filter Caps

- Plastic Brick Mould

- Rubber Parts

- Contact Us

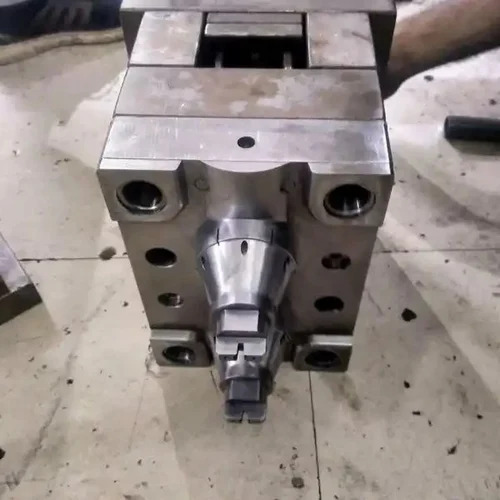

Plastic Moulding Dies

Price 24000 INR/ Piece

MOQ : 1 Piece

Plastic Moulding Dies Specification

- Usage

- Industrial

- Material

- Mild Steel

- Shaping Mode

- Die Casting

- Product Type

- Plastic Moulding Dies

- Color

- Gray

- Warranty

- 1 Year

Plastic Moulding Dies Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-4 Days

About Plastic Moulding Dies

Get the trending solution for your industrial requirements with our hot-selling Plastic Moulding Dies. Crafted from superior mild steel, these wondrous dies offer crowning durability and reliable precision for all die casting applications. Designed in an attractive gray, they suit a wide spectrum of industrial purposes. As a distinguished exporter, manufacturer, producer, service provider, supplier, trader, and wholesaler in India, we guarantee one year of warranty on each product. Choose our Plastic Moulding Dies for unmatched productivity, exceptional strength, and long-lasting performance in your manufacturing processes.

Competitive Advantages & Usage of Plastic Moulding Dies

Our Plastic Moulding Dies deliver superior shaping accuracy, making them a crowning choice for industrial projects requiring consistency and efficiency. Designed for industrial use, they offer reliability and long service life, making them ideal for high-demand settings. The usage is straightforward: simply fit the die into your die casting equipment, ensuring correct alignment for optimal shaping results. Competitive advantages include robust mild steel construction, ease of maintenance, and flexibility for diverse industrial needs.

Delivery Time, Certifications & FOB Port Details

Order processing for Plastic Moulding Dies is streamlined to ensure prompt estimates and smooth dispatch, especially for the domestic market. The average delivery time aligns with industry standards, allowing buyers to plan operations efficiently. All products come certified for quality and durability, supporting peace of mind and stringent industrial requirements. We ship via key FOB ports in India, optimizing logistics for both domestic and international buyers seeking competitive advantages and reliability in delivery.

Competitive Advantages & Usage of Plastic Moulding Dies

Our Plastic Moulding Dies deliver superior shaping accuracy, making them a crowning choice for industrial projects requiring consistency and efficiency. Designed for industrial use, they offer reliability and long service life, making them ideal for high-demand settings. The usage is straightforward: simply fit the die into your die casting equipment, ensuring correct alignment for optimal shaping results. Competitive advantages include robust mild steel construction, ease of maintenance, and flexibility for diverse industrial needs.

Delivery Time, Certifications & FOB Port Details

Order processing for Plastic Moulding Dies is streamlined to ensure prompt estimates and smooth dispatch, especially for the domestic market. The average delivery time aligns with industry standards, allowing buyers to plan operations efficiently. All products come certified for quality and durability, supporting peace of mind and stringent industrial requirements. We ship via key FOB ports in India, optimizing logistics for both domestic and international buyers seeking competitive advantages and reliability in delivery.

FAQs of Plastic Moulding Dies:

Q: How does the die casting process work with these Plastic Moulding Dies?

A: The die casting process involves inserting the Plastic Moulding Die into specialized machinery, where molten plastic is injected under pressure. The die shapes the plastic into precise industrial components efficiently.Q: What are the primary benefits of choosing mild steel for these moulding dies?

A: Mild steel provides superior durability and strength, reducing wear and tear during extensive industrial use, and ensuring a longer product lifespan compared to other materials.Q: When can I expect delivery after placing an order for Plastic Moulding Dies?

A: After order processing and estimate confirmation, delivery times are typically in line with industry practices, depending on your location and order volume. Our team will provide a detailed timeline during purchase.Q: Where are these moulding dies exported from in India?

A: We export these moulding dies from major FOB ports in India, ensuring reliable shipping channels for both domestic and international clients.Q: What certifications support the quality of your Plastic Moulding Dies?

A: Our Plastic Moulding Dies come with industry-standard certifications that attest to their superior quality, robust performance, and adherence to safety regulations.Q: How should Plastic Moulding Dies be maintained for optimal usage?

A: Regular maintenance involves cleaning after use, checking for alignment, and timely lubrication. Routine inspections maintain the dies superior shaping abilities and extend their operational life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Plastic Moulding Dies Category

Plastic Component Mold

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Material : Other, Mild Steel

Usage : Industrial

Warranty : 1 Year

Plastic Mold Maker

Price 20000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Gray

Material : Steel

Usage : Industrial

Warranty : 1 Year

Send Inquiry

Send Inquiry