- होम पेज

- कंपनी प्रोफाइल

-

हमारे उत्पाद

- प्लास्टिक मोल्ड्स

- मोल्ड्स एंड डाई कास्टिंग

- प्लास्टिक मोल्ड

- लाइट ग्लास मोल्ड्स

- प्लास्टिक मोल्ड के लिए मोल्ड बेस

- मोल्ड्स एंड डाई कास्टिंग

- प्लास्टिक मोल्ड बेस

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- मोल्ड्स एंड डाई कास्टिंग

- प्रेशर डाई कास्टिंग

- प्लास्टिक मोल्डिंग मर जाता है

- मोल्डिंग डाई

- संपर्क करें

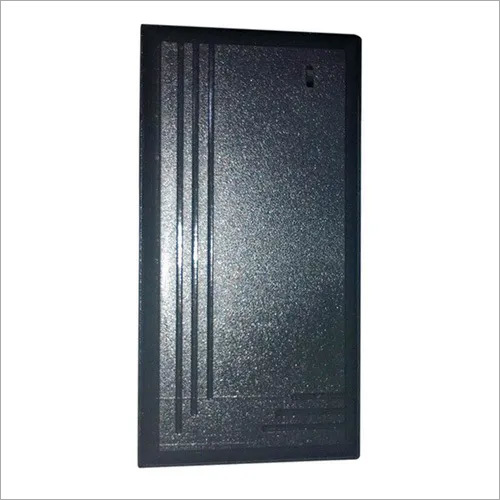

मà¥à¤²à¥à¤¡à¥à¤¸ à¤à¤à¤¡ डाठà¤à¤¾à¤¸à¥à¤à¤¿à¤à¤

मà¥à¤²à¥à¤¡à¥à¤¸ à¤à¤à¤¡ डाठà¤à¤¾à¤¸à¥à¤à¤¿à¤à¤ Specification

- लाइफ स्पैन

- 50,000 - 100,000 Shots

- कोर मटेरियल

- High-grade Alloy Steel

- सहनशीलता

- ±0.05 mm

- काम करने की प्रक्रिया

- मोल्ड बेस

- MS (Mild Steel)

- मटेरियल

- शेपिंग मोड

- पंच डाइस

- Included

- डाई हेड

- Precision Manufactured Die Head

- Weight

- Varies as per mould size

- Coating Type

- High-Performance Anti-Corrosion

- Resistance

- Corrosion and Wear Resistant

- Application

- Metal Casting, Automotive Parts, Industrial Components

- Surface Finish

- Industrial Grade Protective Coating

- Hardness

- HRC 45-55

- Mould Life

- Extended due to special coating

- Standard

- IS Compliant / Customizable

- Manufacturing Technique

- CNC Machined & Heat Treated

About मà¥à¤²à¥à¤¡à¥à¤¸ à¤à¤à¤¡ डाठà¤à¤¾à¤¸à¥à¤à¤¿à¤à¤

Access the acclaimed Coated MS Moulds & Die Casting solutions, recognized for their flawless finish and astounding durability. Redeem the benefit of an industrial grade protective coating, delivering high-performance anti-corrosion resistance and extending mould life to a paragon of reliabilitysupporting 50,000 to 100,000 shots. Engineered with CNC machining and heat treatment, each die boasts outstanding tolerance of 0.05 mm and is IS compliant or customizable. Ideal for metal casting, automotive parts, and various industrial components. Trust the precision, resilience, and remarkable performance whether you are an exporter, manufacturer, supplier, or trader in India.

Applications & Usage of Coated MS Moulds & Die Casting

Coated MS Moulds & Die Casting are extensively used in the manufacturing and shaping of metal casting, automotive components, and industrial machinery parts. Designed for flawless performance, these moulds are an optimal choice for sites engaged in die casting operations, production plants, and industrial workshops. Their paragon-grade coating ensures reliability and durability, making them ideal for high-volume usage in various sectors demanding precision and wear resistance.

Delivery Time, Samples & Supply for Coated MS Moulds & Dies

Benefit from quick shipment and prompt delivery times that align with industry demands. Sample moulds are available on request, typically with a nominal charge ensuring customers evaluate quality before large-scale sale commitment. Boasting an astoundingly scalable supply ability, we cater to diverse order volumes with competitive sale prices. Comprehensive support facilitates seamless acquisition for manufacturers, suppliers, traders, and service providers across India.

Applications & Usage of Coated MS Moulds & Die Casting

Coated MS Moulds & Die Casting are extensively used in the manufacturing and shaping of metal casting, automotive components, and industrial machinery parts. Designed for flawless performance, these moulds are an optimal choice for sites engaged in die casting operations, production plants, and industrial workshops. Their paragon-grade coating ensures reliability and durability, making them ideal for high-volume usage in various sectors demanding precision and wear resistance.

Delivery Time, Samples & Supply for Coated MS Moulds & Dies

Benefit from quick shipment and prompt delivery times that align with industry demands. Sample moulds are available on request, typically with a nominal charge ensuring customers evaluate quality before large-scale sale commitment. Boasting an astoundingly scalable supply ability, we cater to diverse order volumes with competitive sale prices. Comprehensive support facilitates seamless acquisition for manufacturers, suppliers, traders, and service providers across India.

FAQs of Coated MS Moulds & Die Casting:

Q: How does the high-performance anti-corrosion coating benefit the moulds lifespan?

A: The advanced anti-corrosion coating acts as a shield against moisture and chemical exposure, significantly reducing wear and deterioration. This extends the moulds lifespan to an impressive 50,000100,000 shots, ensuring reliable operation over prolonged production cycles.Q: What is the process involved in manufacturing these coated MS moulds?

A: Manufacturing involves CNC machining for accurate dimensions, followed by precision heat treatment and application of a high-grade alloy steel core. The process results in flawless surface finish and exceptional resistance to corrosion and wear.Q: Where are these moulds typically used?

A: Coated MS moulds find applications in metal casting plants, automotive manufacturing units, and industrial component production facilities. Their robust design allows them to function in various high-performance environments.Q: When can I expect my shipment after placing an order?

A: Delivery time may vary based on order size and customization needs, but most shipments are dispatched promptly within industry-standard lead times. Please contact us for specific timelines regarding your request.Q: What is the usage benefit of the 0.05 mm tolerance feature?

A: The precise tolerance of 0.05 mm guarantees accurate shaping and uniformity in die casting results, minimizing errors and enhancing the quality of finished products across high-stakes production applications.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in मोल्ड्स एंड डाई कास्टिंग Category

मोल्ड्स एंड डाई कास्टिंग

लाइफ स्पैन : 10 years

मटेरियल : ,

कोर मटेरियल : Aluminium

शेपिंग मोड : ,

काम करने की प्रक्रिया : ,

पंच डाइस : Precisionmachined

जांच भेजें

जांच भेजें